Smarter Shipping Starts with Knowledge

Shipping Basics

The world of logistics comes with its own language of terms and rules.

This quick guide gives you the essentials – helping you navigate shipping with confidence.

Use it to stay in control, or let us handle the details. Either way, smarter shipping starts here.

Shipping Basics

The volume of your cargo largely determines shipping cost. Two main options are used:

- LCL (Less Container Load) – for smaller volumes. You share container space with others; the goods are consolidated and shipped as a pallet.

- FCL (Full Container Load) – for larger shipments filling a whole container.

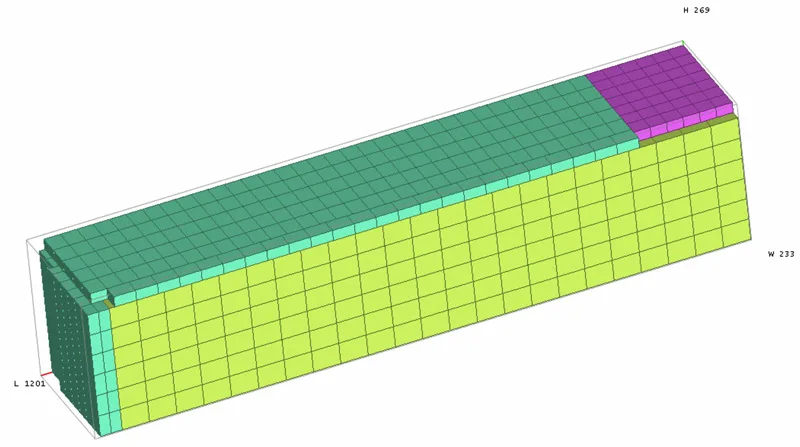

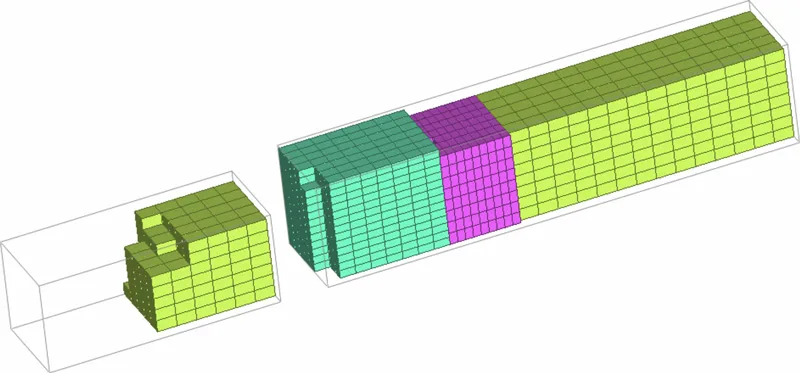

Optimising container use saves both cost and carbon. As shown in illustration A, efficient packing can fit 1,950 cartons in a 40 ft HC container — while in B, poor loading wastes valuable space.

Container Types

There are several types of containers and volumes, but for importers of most products, the following are most relevant:

20 ft DC (Dry Container) – standard 20-foot container. Usable volume: approx. 28 m³.

40 ft DC (Dry Container) – standard 40-foot container. Usable volume: approx. 57 m³.

40 ft HC (High Cube) – taller 40-foot container. Usable volume: approx. 67 m³.

Know the Terms, Master the Flow

Shipping made simple – understand the key terms and timelines to keep your goods moving smoothly from start to finish. Whether we manage the shipment end-to-end or handle delivery on your terms, our goal is the same: reliable, predictable logistics.

Incoterms

Incoterms (International Commercial Terms) are international trade rules that define the responsibilities of buyers and sellers throughout the shipping process. They specify who covers transport, insurance and related costs; where delivery or transfer of goods takes place; whether loading and unloading are included; and at what point the risk passes from seller to buyer. Understanding the chosen Incoterm ensures that both parties have a clear understanding of their obligations, costs and liabilities — reducing the risk of misunderstandings and delays.

The following are the most commonly used Incoterms, showing how responsibilities and liabilities are shared between buyer and seller.

- EXW (Ex Works) – Named Place

The buyer takes responsibility for all costs and risk once the seller has made the goods available at the agreed time and place, e.g. at the seller’s warehouse. - FOB (Free On Board) – Named Port of Shipment

The seller bears all costs and risk until the goods are loaded onto the vessel. After that, responsibility transfers to the buyer. - DDP (Delivered Duty Paid) – Named Place of Destination

The seller covers all costs and risk until the goods are delivered to the agreed destination. The buyer takes over responsibility once the goods are available for unloading at the final delivery point.

Sea Freight Bookings

Sea freight requires forward planning to secure space and keep production and delivery on schedule.

As a rule of thumb, bookings should be made at least 5–6 weeks in advance to allow time for production, documentation and container allocation.

Cut-off – deadlines for documentation and container arrival at the port.

ETD (Estimated Time of Departure) – planned departure date.

ETA (Estimated Time of Arrival) – planned arrival date.

Essential Documentation

Keep track of the key documents required for shipping. The most important include:

BL (Bill of Lading) – contract and proof of ownership between sender and carrier.

CI (Commercial Invoice) – the trade invoice or proforma invoice.

PL (Packing List) – list of items packed in the shipment.

Logistical Challenges

Examples of circumstances that can affect delivery time and shipping costs:

- External factors – weather conditions, strikes or widespread illness can disrupt schedules and cause unexpected delays along the shipping route.

- Transshipments – goods are sometimes transferred between vessels en route. Missing a feeder — the smaller connecting vessel — can delay the shipment by several weeks.

- Port capabilities – not all ports can handle large vessels or high cargo volumes, which may require rerouting or lead to waiting times.

- Container shortages – a lack of available containers can lead to higher freight rates and extended lead times.

- Limited space – overbooked vessels and high seasonal demand can push departure dates forwards and affect delivery predictability.

- Seasonal variations – peak periods such as Chinese New Year and Christmas put extra pressure on production and shipping capacity, often resulting in longer lead times and higher transport costs.

Transit Times From Ho Chi Minh City

This map shows estimated sea freight transit times, in days, from Ho Chi Minh City — where our bags are shipped from — to major European ports. Transit duration depends on route, vessel type and destination, as well as seasonal demand and external conditions. While schedules may vary, the overview provides a useful indication of how long shipments typically take under normal circumstances. Factoring in these lead times supports better planning, more reliable deliveries and a stronger overall logistics performance.